Making Technology Simple

Design • Install • SupportBest Technology Solution Services Company in South Florida

OnPoint Tech Systems is a comprehensive provider of technology solutions for homes and businesses throughout South Florida. We provide professional networking, automation, and security solutions to meet the needs of homeowners and businesses of all sizes. We can design and install high-quality networking, audio/visual, security, and access control solutions that are scalable and efficient.

With our solutions, businesses can optimize their operations and enjoy a high level of security. Home and business owners can access, monitor, and control their systems from anywhere with our automation solutions. With the cloud, you can access your work from anywhere, allowing you to work without having to come into the office.

Our tech experts are prepared to handle jobs of any size and can help to design and customize the solutions you need for your home or business. To learn how we can create a solution for your needs, contact OnPoint Tech Systems today to request a quote.

SERVICES

What We Do

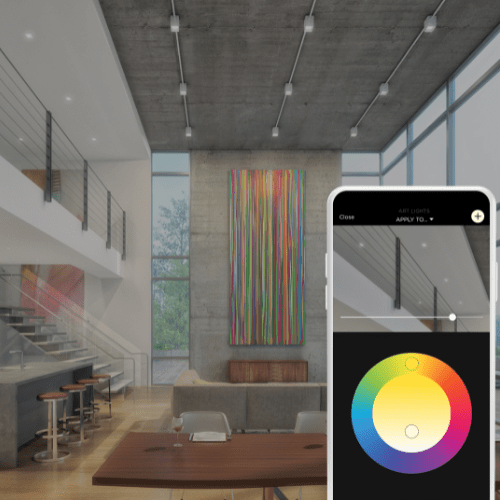

Automation

We offer the latest smart automation technology to bring your home or business into the 21st century. With our automation technology, you can control the systems in your home or business from a central controller, your tablet, or your smartphone. Control your lights, locks, appliances, stereo, and television with a click of a button whether you are at home or are away.

Audio | Video

OnPoint Tech Systems can help you to design and install high-grade audio and video equipment throughout your home or business. Enjoy the theater-quality sound and picture quality with your home theater and high-resolution audio system. We expertly install your equipment and mount TVs in a way that seamlessly blends in with your decor. Our audio/visual equipment comes with universal remote controls for simplicity throughout your home.

Lighting

Onpoint Tech Systems offers beautiful and innovative architectural LED lighting fixtures from many major leading brands to meet the needs of any design home or business. Aside from the latest aesthetics, our lighting fixtures offer customer and tunable lighting color temperatures for any space.

Automatic Shades

Motorized blinds & shades appear at the touch of a button and disappear when you don’t need them. Perfect for all indoor living spaces, these custom-made and professionally installed blinds & shades give you the convenience to easily manage room lighting and privacy.

Video Surveillance

Our video surveillance experts inspect your business or residence to design the best digital surveillance security solutions to meet your needs. You can rely on our high-resolution smart security cameras to protect your business or home. With our IP security solutions, you can record and watch from your computer, tablet, or smartphone from anywhere. We use the highest-quality branded equipment to guarantee reliability and precise performance.

Network | Wi-Fi

We offer comprehensive network solutions to meet the needs of your business or home. Our network professionals can design, configure, and install your network. We also offer VPN configuration and setup services and provide solutions for your WiFi hot spot and hospitality needs for your customers. With our wireless networking solutions, you can feel confident that you will have secure and reliable access. We also provide troubleshooting and maintenance for connection problems and wireless router or modem issues.

Backup Power | Distribution

As an authorized Liebert and Vertiv Dealer, OnPoint Tech System offers products and services for these industry-leading manufacturers. You can enjoy a total backup power solution that includes services, software, and hardware that maximize your business’s capacity and efficiency. We can install UPS backup power systems, precision cooling systems, PDUs, and system monitoring. Our solutions are scalable, allowing you to meet the changing needs of your growing business.

BRANDS

Our Brands

TESTIMONIALS